FILLED & WIRE CUT LINE

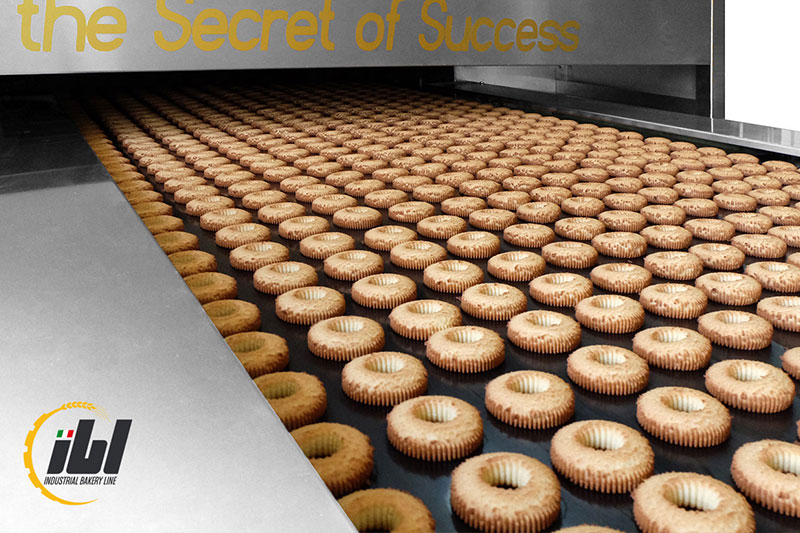

The industrial line dedicated to the production of coextruded, syringed and wire cut biscuits, consists of in the preparation of a dough mixture with the use of one or more planetary mixer with extractable bowls of adequate size compared to the requested capacity. A lifting then transfers the dough into the hopper of the processing head, which can be dedicated to a single production or to all productions of: co-extruded biscuits (round, strudel shaped, etc.) with fillings of cream, jam, chocolate; syringed biscuits (Novellino, Crumiro, etc.); wire cut biscuits with moulds for all possible shapes.

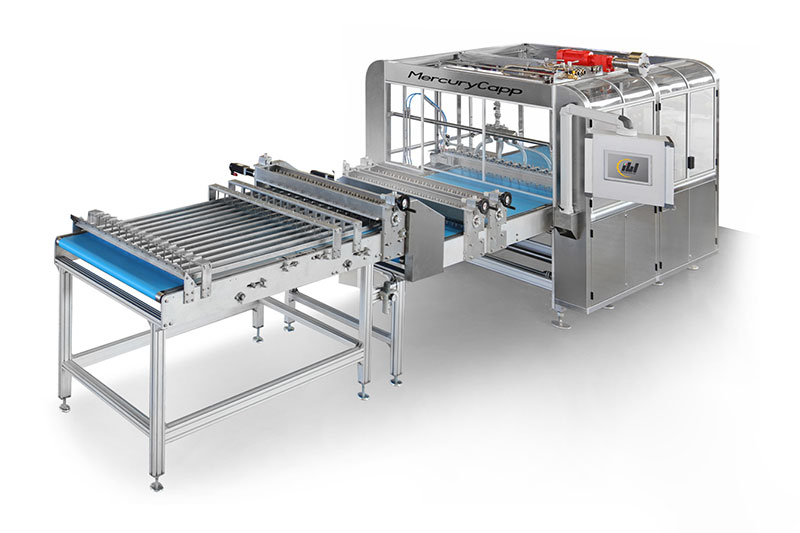

The machining head is positioned in front of or directly on the oven loading bench, and the baking conveyor belt is made of a blue sheet of a specific kind of steel. The oven with radiant cyclothermic heating system allows you to obtain a perfectly uniform baking. IBL is able to offer lines that adapt to the needs of their customers, with different productivities and configurations, also in this case that depend on the width of the production layout that can vary from 600 mm up to 1800 mm.

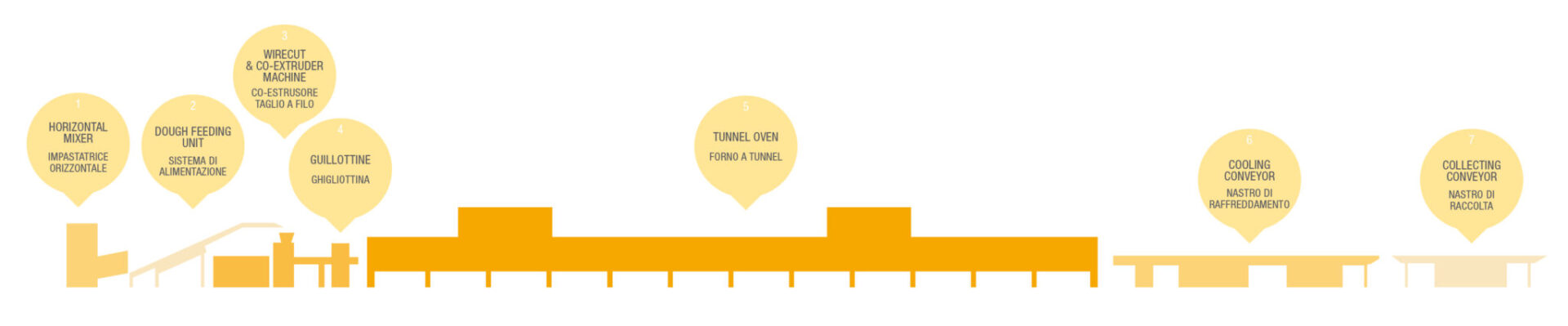

EXAMPLE OF

FILLED & WIRE CUT LINE

HORIZONTAL MIXER

DOUGH FEEDING UNIT

WIRECUT E CO-ESTRUDER MACHINE

TUNNEL OVEN

COOLING CONVEYOR

GUILLOTTINE

COLLECTING CONVEJOR

1. HORIZONTAL MIXER

Designed to form mixtures from crackers, hard biscuits, shortbread biscuits, extruded products and other types of leavened products, it is built in various models with capacities from 200 to 1100 litres.

2. DOUGH FEEDING UNIT

The star feeder receives the dough from the mixer and cuts the dough in pieces for the smooth feeding of the sheeter. The feeder is composed of a stainless steel hopper of about 350 liters lined with anti-sticking plastic and of a bottom star cutter with a sloped conveyor.

3. WIRECUT & CO-EXTRUDER

The machine is designed to produce deposited cookies and wire cut.

It consists of an extrusion head, where inside are housed three grooved rollers and the profile extrusion of the paste.

4. GUILLOTTINE

The machine cuts at regular intervals the product present on the lower conveyor through the mechanical action of a blade eventful of cams which allows vertical translation for the cutting phase and the horizontal translation to follow the movement of the product.

5. TUNNEL OVEN

Cyclotherm oven is suitable for baking of products ranging from cupcake, Swiss roll and other sponge products, extruded, wire cut and rotary moulded soft dough products through to hard/sweet and bread.

Oven consist of assembled modular structure supported by steel frame fixed to the floor.

6. COOLING CONVEYOR

Structure is in stainless steel. Foodgrade plastic belt FDA approved. Modular structure for easy assembling. Roller rubber covered for drive belt. Equipped with towing gear box with variable speed.

7. COLLECTING CONVEYOR

Positioned at the end of line production. For recovery stacked and take product for wrapping machines. Structure is in stainless steel. Foodgrade plastic belt FDA approved. Modular structure for easy assembling. Roller rubber covered for drive belt. Equipped with towing gear box with variable speed.