Your Product Secret's

BAKERY LINE TECHNOLOGY FOR MEDIUM AND HIGH VOLUMES

TASTE THE DIFFERENCE

The production layouts for bakery lines created by IBL – Industrial Bakery Line are not only designed in-house but, more importantly, manufactured at our company’s facility and headquarters near Verona.

The production layouts and machinery constructed by IBL – Industrial Bakery Line reflect the cutting-edge standards of the industry and ensure the most suitable custom solutions, consistently innovative and cost-effective, for any bakery industrial environment and economic scenario.

BISCUIT, COOKIE AND CAKE

Cookies, soft biscuits, hard biscuits and crackers from different content of sugar and fat and the most varied forms.

BREAD

Bread of every kind and shape, pizza, pita and endless personalizations of the world of bakery.

Also this month, we would like to monitor the real-time performance of our website. We are proud to confirm its success in many locations around the world.

Our Sales Department is fully available to provide you with any information, clarifications, or quotations you may need. Your enthusiasm serves as a strong motivator for our dedication: elevate your business with industrial bakery line technology!

STORYTELLING

HOW CRACKERS ARE BORN

It is a pleasure for us to tell you directly from within our Company the steps that lead to the realization of our products, from the smallest lamination machine, through the production of ovens, up to complete automatic production lines.

Today we want to show you some frames of the production of a hybrid oven, the heart of the production of mini crackers, consisting of a first part with direct gas and a second part with convection.

BISCUIT LINE PRODUCTION

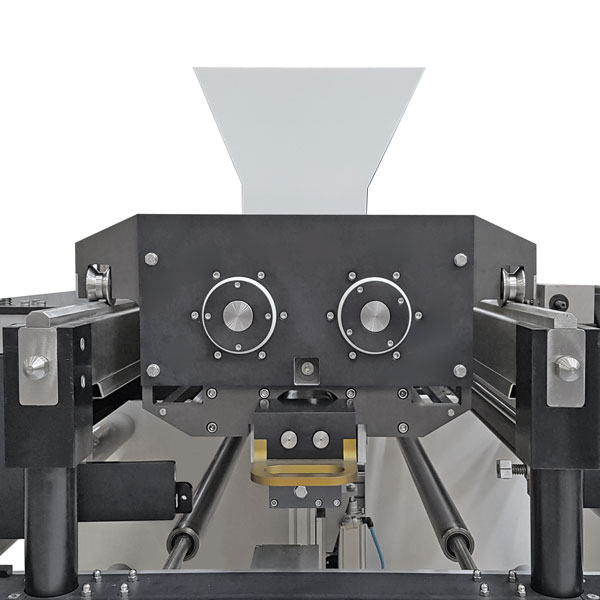

DEPOSITOR: THE EXPERIENCE

IN THE DOSING PASTRY

Designed for industrial use and to offer the maximum versatility, the IBL depositor is the ideal machine for depositing or extruding in continuous or with wire cut, swirl, diaphragm on dedicated belt or on oven steel band steel band a wide range of doughs, from fluids to viscous ones, also with nuts, chocolate, candies and so on.

BISCUIT & COOKIE LINES

GIVE YOUR BUSINESS

THE BEST FRAGRANCE,

TASTE AND ASPECT

IBL Industrial Bakery Line designs and builds industrial layouts

and turnkey automated machinery for the complete-cycle

production of bread and biscuits.

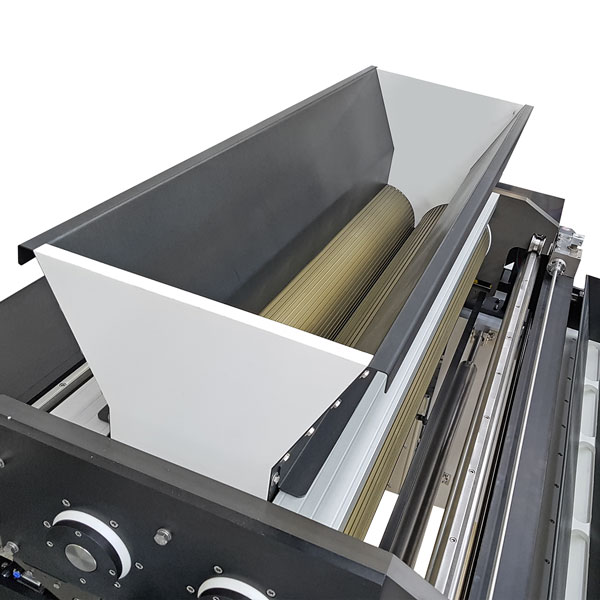

FOCUS

YOUR BEST CHOICE:

THE LAMINATION LINE PRODUCTION

There are many aspects that make you prefer a product.

The lamination line, improved in design and made more stable

in components, is undoubtedly one of these.

YOUR SOLUTION

FOR THE BEST ROASTING

IBL provides its experience in the production of industrial automatic rusks lines, customized in capacity, weight and size, depending on the specific needs of the customer. However the wheat flour is mixed and portioned or laminated and cut, and then rolled in loaves and automatically panned in pans that gives the shape. The leavening phase can be done either way with lids on pans, before or after baking; alternate product can be the dome shaped bread that is baked without lid. After baking, the loaves pass in the seasoning cell where the loaves cool and gain better consistency for slicing and the second oven toasts the bread slices and gives to the product crispness, high energy, appearance, fragrance and in addition reduces the product humidity and increases digestibility. IBL lines firstly allow the production of classic, one or two colors, but also whole meal, malt, cereal, light rusks.