ROLLS & BREAD LINE

IBL has the know-how for all kinds of bread line based on the flour used, ingredients or elements incorporated in the dough or on the surface, sizes and shapes, leavening, baking, etc.

The technology used by IBL operates with special extruders also called No-Stress that manage to preserve the structure of the dough and maintain the high level of quality of the final product.

Depending on the configuration of the IBL line, it is possible to produce a variety of products starting from Ciabatta Bread, Buns, Baguette, Toast … etc.

As with other production lines, this IBL line also uses only high-quality materials, and thanks to the experience accumulated over the years, IBL is proud of the robustness and flexibility, ease of cleaning, simplified control, ease of maintenance, and high accuracy in final weights of its lines.

The configuration shown in this page is just one of the possible applications of our lines. Our specialists are pleased to share our experience in helping you decide your ideal system.

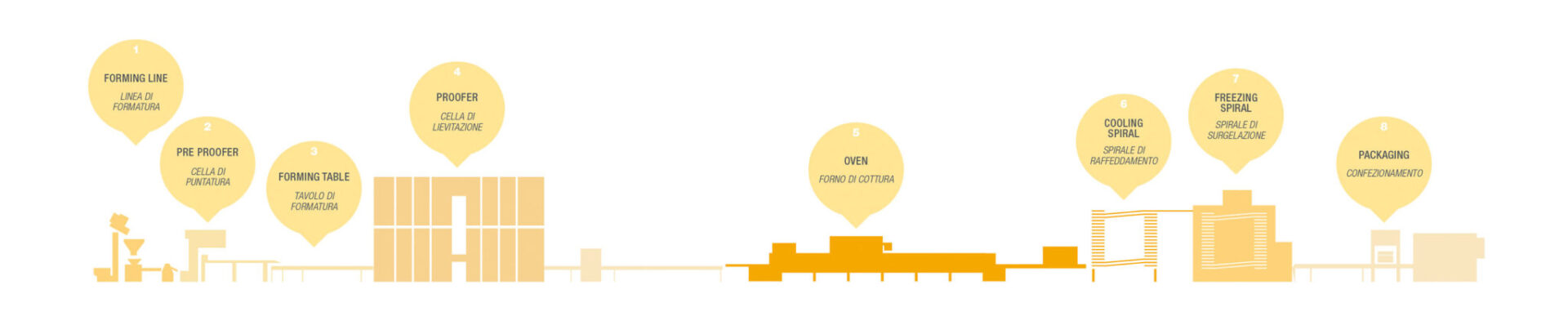

EXAMPLE OF

BREAD & ROLLS LINE

FORMING LINE

PRE PROOFER

FORMING TABLE

PROOFER

OVEN

COOLING SPIRAL

FREEZING SPIRAL

PACKAGING

1. FORMING LINE

Composed from: spiral mixer, bowl, elevator bowl, overhopper divider, volumetric divider, long loaf moulder.

2. PRE PROOFER

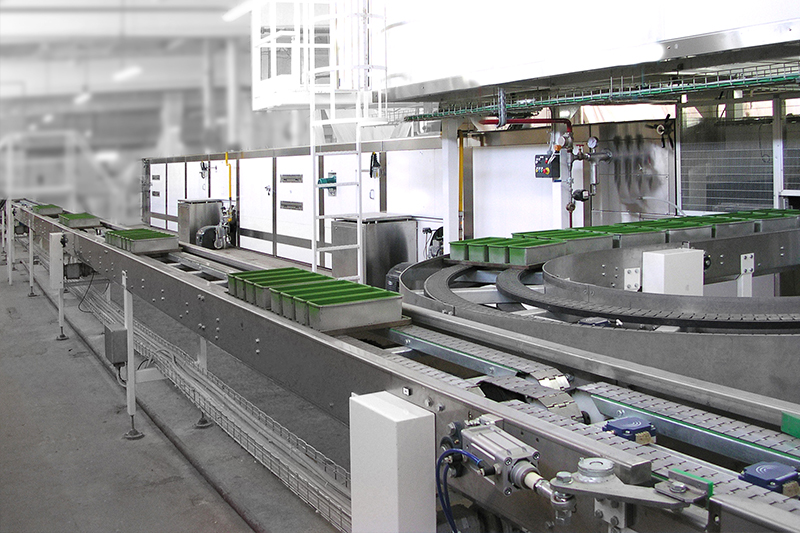

Suitable to provide rest to the spherical pieces of dough for a pre-determined period according to the production capacity. The intermediate proofer is available with a number of pockets according to the required resting time and to the production capacity/hour.

3. FORMING TABLE

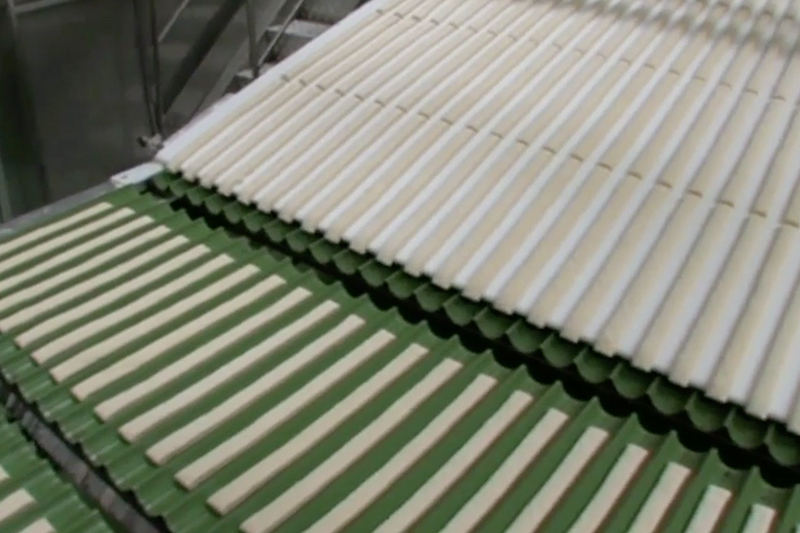

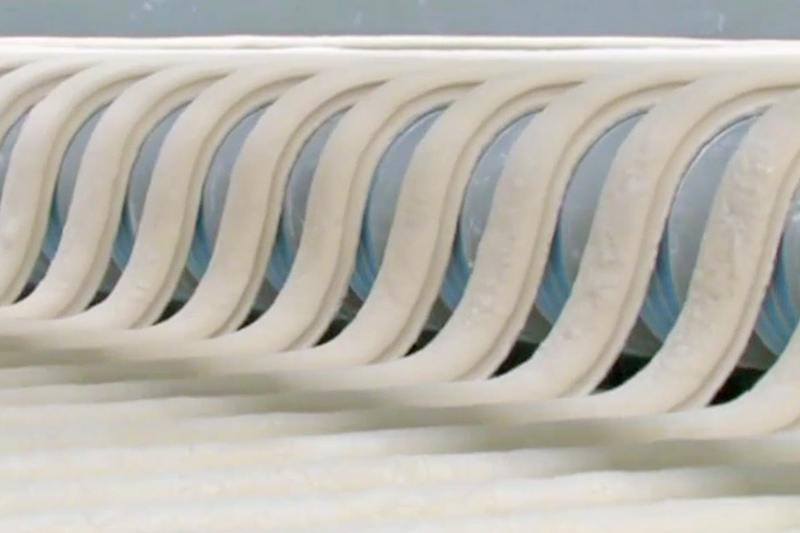

The technology used by IBL operates with special extruders also called No-Stress that manage to preserve the structure of the dough and maintain the high level of quality of the final product.

4. PROOFER

The cell receives the pieces of dough from the forming machines and assures to them the maintenance of thermo-hygrometric conditions controlled for the required time which is enough to ensure the correct livening of the product.

5. OVEN

Particularly suitable for large laboratories, they allow a variety of products to be baked, from biscuits to medium or large-sized bread.

6. COOLING SPIRAL

The spiral cooling conveyor is employed for the thermal treatment of food products both loose and packed for drying, sterilizing, cooling and freezing or leavening different kind of good. The spiral is built essentially by a driving system and a belt conveyor.

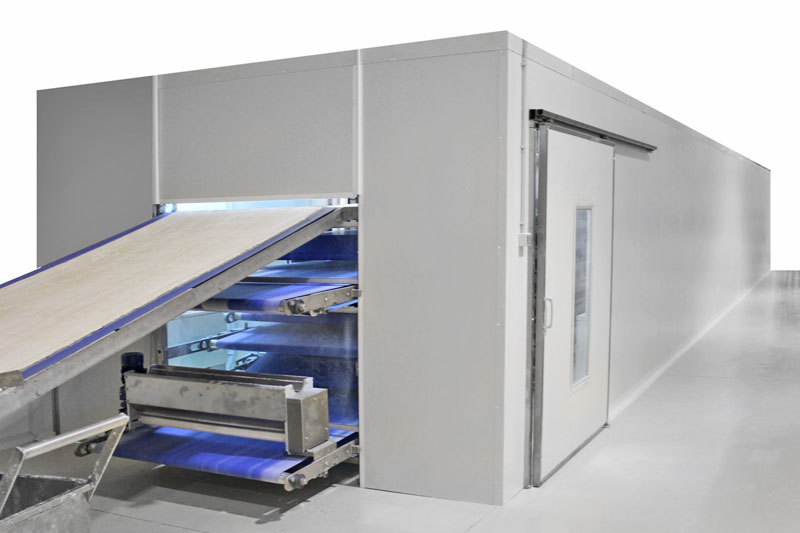

7. FREEZING SPIRAL

The spiral is positioned within a cell of isolation that allows the achievement of the optimum temperature for the deep-freezing of the product. Inside the insulated chamber they are inserted which form the evaporators and distribute the flow of air, making the temperature uniform in the environment and increasing the heat exchange between product and air.

8. PACKAGING

The finished product, at the end of all the processing, is sent to the automatic packaging.